Blog

Geekzilla Autos: Exploring Innovation in the Automotive World

In today’s fast-paced digital era, automotive enthusiasts crave platforms that provide authentic information, in-depth reviews, and the latest updates about cars. Geekzilla Autos has emerged as a trusted source where technology meets automotive passion. From car reviews to innovations in the electric vehicle market, Geekzilla Autos captures the essence of modern driving experiences.

What is Geekzilla Autos?

Geekzilla Autos is an online platform dedicated to everything related to automobiles. It covers a wide spectrum of topics such as vehicle reviews, comparisons, maintenance tips, car technology trends, and future innovations. Unlike traditional automotive blogs, Geekzilla Autos focuses on merging tech-driven insights with automotive culture, appealing not only to car owners but also to tech-savvy readers.

Why Geekzilla Autos Stands Out

Comprehensive Car Reviews

One of the core strengths of Geekzilla Atos is its in-depth car reviews. Every article is crafted with detailed analysis, covering aspects like design, performance, fuel efficiency, safety features, and affordability. Whether readers are looking into sedans, SUVs, or electric cars, Geekzilla Atos provides unbiased insights that help buyers make informed decisions.

Focus on Technology

In a world where cars are becoming smarter, Geekzilla utos stands apart by emphasizing automotive technology. From AI-powered driving systems to the evolution of electric vehicle batteries, the platform dives deep into how innovations are shaping the industry.

Accessibility for Beginners and Experts

Unlike highly technical automotive sites, Geekzilla Auos maintains a balance in its content. Beginners can easily understand the basics, while experts still find value in the advanced discussions. This inclusivity makes it an engaging hub for all levels of car enthusiasts.

The Role of Geekzilla Autos in the EV Revolution

The automotive industry is rapidly shifting toward sustainability, and Geekzilla Auos dedicates extensive coverage to electric vehicles (EVs). Articles on EV infrastructure, charging stations, and government incentives give readers clarity about transitioning to eco-friendly cars. The platform also compares EV models, helping consumers choose between brands like Tesla, Rivian, and legacy automakers.

Geekzilla Autos and Car Culture

Cars are more than just machines—they’re part of lifestyle and culture. Geekzilla Atos often explores automotive communities, fan events, and collector stories that highlight the emotional connection between drivers and their vehicles. From vintage car exhibitions to modern supercar showcases, it captures the excitement and passion of the auto world.

Expert Advice and Maintenance Tips

Geekzilla Auos isn’t just about trends and reviews. It also offers practical advice for car owners. Readers can find:

-

DIY maintenance guides – covering oil changes, tire care, and brake checks.

-

Seasonal driving tips – ensuring safety during winter or rainy conditions.

-

Car care product recommendations – from waxes to cleaning kits that extend vehicle lifespan.

This combination of knowledge makes Geekzilla Atos a reliable companion for both new and experienced car owners.

Community Engagement and Reader Value

Geekzilla Auts thrives on community engagement. It encourages readers to share experiences, contribute opinions, and participate in discussions about vehicles and technology. This interactive approach sets it apart from one-way automotive blogs, making it a living community where ideas are exchanged.

The Future Vision of Geekzilla Autos

Looking ahead, Geekzilla Auos aims to expand its coverage into emerging automotive segments such as autonomous vehicles, hydrogen fuel technology, and mobility-as-a-service platforms. By consistently adapting to industry changes, the platform ensures readers stay updated on the most groundbreaking trends.

Why Automotive Enthusiasts Trust Geekzilla Autos

Trust is the foundation of Geekzilla Atos. Its unbiased reviews, verified sources, and transparent reporting create a trustworthy space for readers. Instead of promoting a particular brand, it prioritizes accuracy and reader value, which has cemented its credibility among global audiences.

Final Thoughts on Geekzilla Autos

In a constantly evolving automotive landscape, Geekzilla Autos stands as more than just a website—it is a gateway into the future of cars. By combining technology, culture, and practical advice, it delivers a complete automotive experience. Whether you’re an everyday driver, a tech enthusiast, or a collector of rare models, Geekzilla Autos ensures you’re always informed and inspired.

Blog

The Social and Digital Impact of คลิปหลุด in the Modern Internet Era

Blog

Weld Symbol Details: A Complete Guide to Welding Symbols and Their Meanings

When it comes to fabrication and engineering drawings, weld symbol details play a vital role in communicating the type, size, and location of welds required for a structure. These symbols act as a universal language between designers, engineers, and welders, ensuring that every joint and connection is accurately produced. Understanding not only improves productivity but also minimizes errors and material wastage.

In this comprehensive guide, we’ll break down every important aspect of , including their meaning, classification, and placement. By the end, you’ll have a complete understanding of how to read and interpret weld symbol in real-world applications.

Understanding the Basics of Weld Symbol Details

Before diving into complex illustrations, it’s crucial to grasp the fundamental concept of weld symbol details. A is essentially a graphical representation placed on engineering drawings to specify the type of weld to be performed. These details eliminate the need for long written instructions, making the blueprint clean and universally understandable.

Key Components of Weld Symbols

A standard consists of several parts. Each element conveys a specific meaning that guides the welder:

| Component | Description |

|---|---|

| Reference Line | The horizontal line on which the weld symbol is placed |

| Arrow | Points to the location of the weld on the drawing |

| Tail | Optional element used for additional notes or specifications |

| Basic Weld Symbol | Represents the type of weld (fillet, groove, spot, etc.) |

| Dimensions and Angles | Indicate size, length, or depth of the weld |

| Supplementary Symbols | Include finishing instructions or contour details |

Each of these elements contributes to the precision and clarity of the welding instructions.

Types of Weld Symbol Details

Different welding processes require different symbols. Let’s explore the most common weld symbol used in industrial drawings.

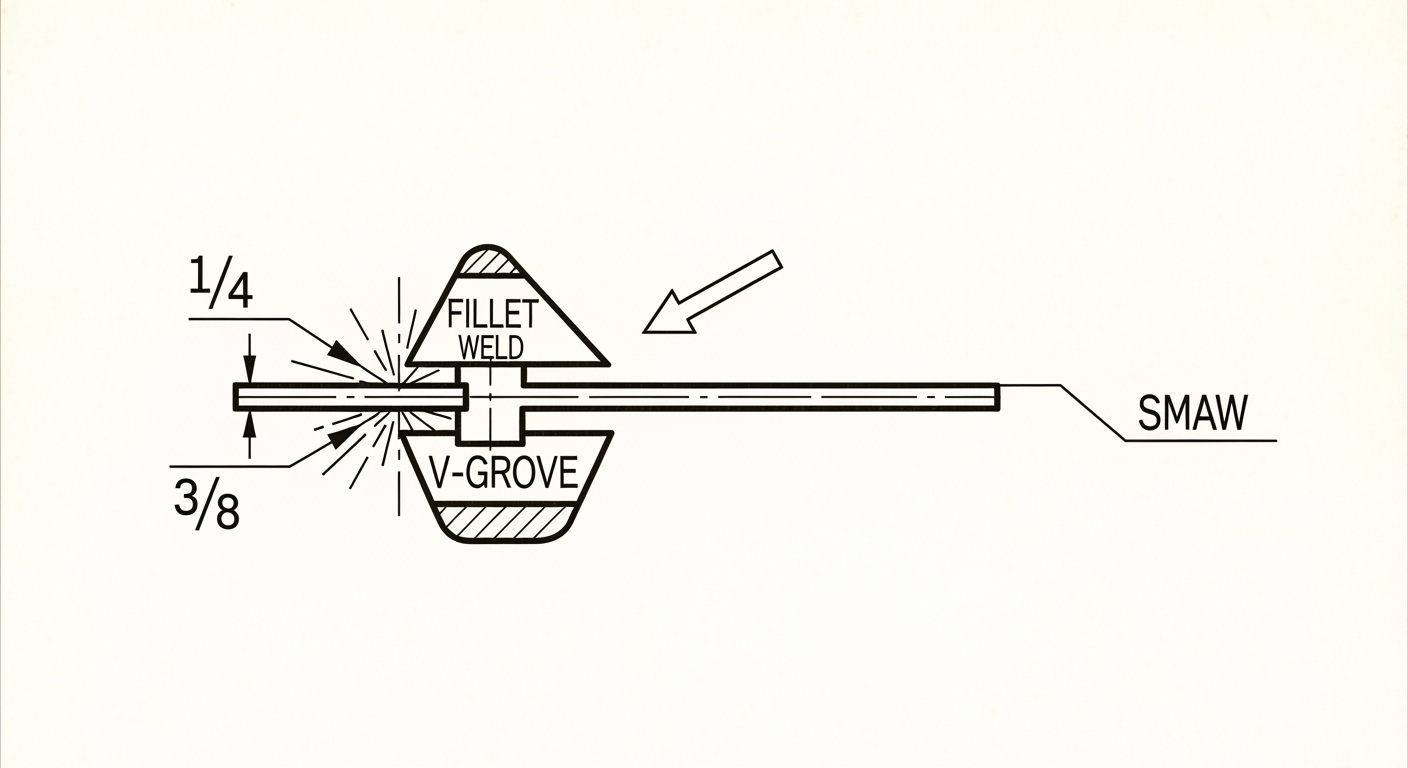

Fillet Weld Symbol

The fillet is one of the most commonly used. It’s represented by a triangular shape, symbolizing a weld that joins two surfaces at approximately right angles. Fillet welds are used in lap joints, corner joints, and T-joints.

| Feature | Fillet Weld Detail |

|---|---|

| Shape | Triangle on reference line |

| Placement | Arrow or other side |

| Common Joints | Lap, Corner, T-Joint |

Groove Weld Symbol

Groove welds are used when two pieces are placed edge-to-edge. The groove varies depending on the groove type, such as square, V, U, or J groove.

| Groove Type | Symbol Representation | Application |

|---|---|---|

| Square Groove | Two parallel lines | Thin materials |

| V-Groove | V-shaped symbol | Medium thickness |

| U-Groove | Curved “U” shape | Thick sections |

| J-Groove | Half “U” shape | Uneven thickness |

These ensure proper penetration and strength in welded joints.

Spot and Seam Weld Symbols

Spot welds are used primarily in sheet metal applications, while seam welds are continuous lines formed by multiple spot welds in sequence.

| Type | Symbol | Use |

|---|---|---|

| Spot Weld | Circular symbol | Sheet metal fabrication |

| Seam Weld | Straight line with periodic circles | Automotive and industrial panels |

Plug and Slot Weld Symbols

Plug and slot welds fill holes or elongated openings in one member of a joint. These weld symbol help provide additional strength where necessary.

| Type | Symbol Shape | Purpose |

|---|---|---|

| Plug Weld | Filled circle | Strengthen overlapping joints |

| Slot Weld | Filled rectangle | Reinforce elongated openings |

Reading and Interpreting Weld Symbol Details

To effectively interpret , one must understand where the symbol is placed relative to the reference line.

-

Arrow Side Welds: When the symbol is below the reference line, the weld should be made on the arrow side of the joint.

-

Other Side Welds: When the symbol is above the reference line, the weld should be made on the side opposite the arrow.

-

Both Sides Welds: When symbols appear on both sides of the reference line, it indicates welding on both sides of the joint.

Example Interpretation Table

| Symbol Position | Weld Location | Example Application |

|---|---|---|

| Below Line | Arrow Side | Fillet weld on lower joint |

| Above Line | Other Side | Groove weld opposite arrow |

| Both Sides | Double Weld | T-joint with two fillets |

Interpreting these correctly ensures accurate weld placement and structural strength.

Supplementary Weld Symbol Details

Supplementary symbols add further information about the shape or finishing of a weld. They often appear alongside the basic to provide complete welding instructions.

| Supplementary Symbol | Meaning | Example Use |

|---|---|---|

| Convex | Weld face is raised | Reinforced joints |

| Concave | Weld face is indented | Flush surface finishes |

| Flat | Weld face is level | Aesthetic surfaces |

| Field Weld | Indicates welding performed on-site | Construction welding |

| Contour Finish | Specifies grinding or machining | High-precision work |

These details ensure that the final weld meets both aesthetic and structural requirements.

Placement Rules for Weld Symbol Details

Proper placement of on drawings is essential for avoiding confusion. The American Welding Society (AWS) has standardized guidelines to ensure consistency across industries.

-

The reference line should always remain horizontal.

-

The arrow must clearly point to the joint where welding is required.

-

The symbol orientation (above or below the line) defines the weld side.

-

Dimensions and notes should be legible and placed neatly to avoid overlap.

Following these placement rules ensures clear communication between engineers and welders, preventing costly mistakes in fabrication.

Applications of Weld Symbol Details in Industry

The use of spans across various industries, from automotive and aerospace to shipbuilding and construction. Accurate interpretation of these details enhances manufacturing efficiency and product reliability.

| Industry | Use of Weld Symbols | Outcome |

|---|---|---|

| Automotive | Sheet metal fabrication | High-strength joints |

| Construction | Structural steelwork | Safety and durability |

| Aerospace | Precision components | Lightweight integrity |

| Shipbuilding | Hull and frame assembly | Water-tight welds |

Understanding weld symbol helps technicians and engineers achieve precise, strong, and aesthetically pleasing welds.

Common Mistakes in Reading Weld Symbol Details

Even experienced welders can sometimes misinterpret symbols, leading to welding errors. Some common mistakes include:

-

Confusing arrow side with the other side.

-

Ignoring supplementary symbols.

-

Misreading weld size or length.

-

Overlooking field weld indications.

Avoiding these errors requires proper training and attention to the drawing specifications.

Advantages of Understanding Weld Symbol Details

Knowing how to read and apply weld symbol provides several benefits:

-

Improved Communication: Simplifies interaction between designers and fabricators.

-

Reduced Errors: Minimizes the chance of incorrect welds.

-

Efficiency: Speeds up the production process by reducing ambiguity.

-

Cost-Effectiveness: Prevents rework and material waste.

-

Safety: Ensures structural integrity and compliance with standards.

Conclusion

Mastering weld symbol details is an essential skill for anyone in the fabrication, engineering, or welding industry. These symbols provide a standardized way to communicate complex information about joints, weld types, and finishes. By understanding the placement, meaning, and variations of weld symbols, professionals can ensure quality, safety, and efficiency in every project.

Whether you’re a student learning the basics or a professional seeking deeper knowledge, paying attention towill significantly enhance your technical capabilities and ensure flawless welding results.

Blog

Resistance Welding: A Complete Guide to Its Process, Types, and Industrial Applications

Resistance welding is a fundamental process in modern manufacturing that joins metal pieces through the application of heat generated by electrical resistance. The process is highly efficient, reliable, and widely used in the automotive, aerospace, and electronics industries. In simple terms, resistance welding uses electric current and pressure to bond two or more metal surfaces without requiring filler materials or flux.

The technique is renowned for producing clean joints, reducing waste, and ensuring consistent weld quality. Due to its automation compatibility and cost-effectiveness, resistance welding continues to be a cornerstone in industrial metal fabrication.

Understanding the Working Principle of Resistance Welding

At the heart of resistance welding lies a simple scientific principle: when an electric current passes through a resistive material, heat is generated according to Joule’s Law. The amount of heat generated depends on three factors — the current (I), resistance (R), and time (t).

The formula governing this process is:

| Parameter | Description | Symbol | Unit |

|---|---|---|---|

| Current | Electric current flowing through metals | I | Amperes (A) |

| Resistance | Electrical resistance of metal contact | R | Ohms (Ω) |

| Time | Duration of current flow | t | Seconds (s) |

| Heat Generated | Energy produced at contact area | H | Joules (J) |

The formula H = I² × R × t explains that the heat generated at the interface causes the metal surfaces to soften and fuse together under pressure. Once the desired temperature is achieved, the current is stopped, and the molten joint solidifies to form a strong weld.

Types of Resistance Welding

There are several types of resistance welding techniques, each suited for specific applications and metal thicknesses. The most commonly used types include:

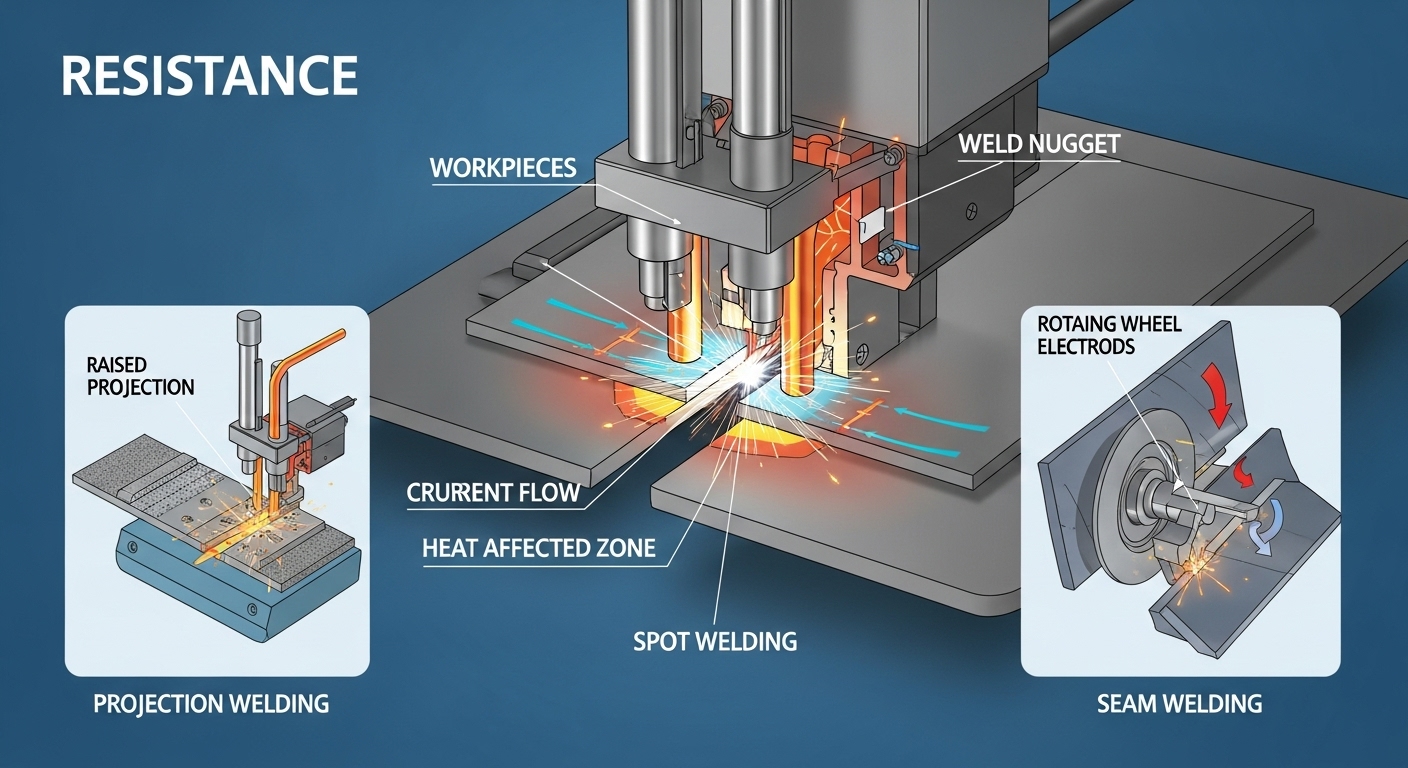

1. Spot Welding

Spot welding is the most common form of resistance welding. It involves clamping two metal sheets between copper electrodes and applying current through the spot where they meet. The generated heat melts the metals, creating a localized weld known as a “nugget.”

Spot welding is extensively used in the automotive industry for joining car body panels and metal components due to its speed and simplicity.

2. Seam Welding

Seam welding is a variation of spot welding where rotating wheel electrodes continuously move over overlapping sheets. This process produces a series of overlapping welds, forming a leak-proof seam.

It is ideal for manufacturing fuel tanks, radiators, and sealed containers that require airtight joints.

3. Projection Welding

Projection welding uses raised projections or embossed areas on one of the metal surfaces to localize the heat and current flow. This technique allows multiple welds to be made simultaneously, making it efficient for mass production.

Projection welding is commonly used in electrical components, nuts, and bolts where precision and strength are critical.

4. Flash Butt Welding

Flash butt welding involves clamping the ends of two metal pieces and bringing them into contact under a controlled current. Sparks or “flashes” are produced due to resistance, and when the temperature reaches a suitable level, pressure is applied to forge the joint.

This method is ideal for joining railway tracks, pipes, and rods, ensuring strong and uniform welds without additional materials.

Equipment Used in Resistance Welding

The success of resistance welding depends largely on the quality of the equipment used. The primary components include:

| Component | Function | Material/Type |

|---|---|---|

| Power Source | Supplies electric current | AC or DC Transformer |

| Electrodes | Conducts current and applies pressure | Copper Alloys |

| Control System | Regulates current, pressure, and time | Microprocessor-based |

| Cooling System | Maintains electrode temperature | Water-cooled system |

| Workpiece Holder | Positions metal sheets accurately | Adjustable Clamp |

Each component must work harmoniously to ensure consistent heat generation, precise timing, and uniform weld strength.

Advantages of Resistance Welding

Resistance welding offers several significant advantages that make it a preferred choice in various manufacturing sectors:

-

High Speed and Efficiency: The process is extremely fast and ideal for automated production lines.

-

Strong and Reliable Joints: Welded areas are robust and resistant to mechanical stress.

-

No Need for Filler Materials: Reduces cost and simplifies the welding process.

-

Minimal Distortion: Localized heating prevents warping of the metal sheets.

-

Clean Process: Produces no smoke, sparks, or harmful fumes, making it environmentally friendly.

-

Cost-Effective for Mass Production: Especially suitable for high-volume manufacturing industries.

Disadvantages of Resistance Welding

While resistance welding offers many benefits, it also has some limitations:

-

Limited to Thin Sheets: Not suitable for very thick materials.

-

High Initial Cost: Equipment and maintenance can be expensive.

-

Limited Joint Geometry: Difficult to weld irregular or non-overlapping surfaces.

-

Electrode Wear: Electrodes degrade over time, affecting weld quality.

Despite these drawbacks, the process remains widely used because of its consistency and automation potential.

Applications of Resistance Welding

The applications of resistance welding span across multiple industries. Its versatility and efficiency make it indispensable in:

| Industry | Common Application |

|---|---|

| Automotive | Body panels, chassis, fuel tanks |

| Aerospace | Aircraft skin, brackets, and frames |

| Electrical | Motor components, switches, connectors |

| Railways | Rail joints, axles, couplings |

| Household Appliances | Washing machines, refrigerators, heaters |

Resistance welding ensures high productivity and repeatability, which are crucial for large-scale manufacturing environments.

Comparison Between Resistance Welding and Arc Welding

| Aspect | Resistance Welding | Arc Welding |

|---|---|---|

| Heat Source | Electrical Resistance | Electric Arc |

| Filler Material | Not Required | Usually Required |

| Automation | Highly Automated | Partially Automated |

| Surface Finish | Smooth and Clean | Often Requires Grinding |

| Application | Thin Metals | Thick and Complex Structures |

This comparison highlights that resistance is best suited for high-volume, thin-metal production where speed and cleanliness are priorities.

Quality Control in Resistance Welding

Ensuring weld quality is essential for maintaining structural integrity. Common quality control measures include:

-

Weld Nugget Inspection: Measuring diameter and shape of the weld spot.

-

Destructive Testing: Pull and peel tests to assess strength.

-

Non-Destructive Testing: Ultrasonic or X-ray examination for internal defects.

-

Electrode Maintenance: Regular cleaning and replacement to prevent wear.

Maintaining proper current, pressure, and timing is key to achieving consistent weld results.

Future of Resistance Welding

The future of resistance welding is moving toward smart automation and precision control. With advancements in artificial intelligence, real-time monitoring systems, and robotic integration, the process is becoming even more efficient and adaptive.

Innovations like adaptive welding systems and AI-powered quality analysis are enhancing accuracy, reducing waste, and minimizing human intervention. Moreover, sustainable practices such as energy-efficient power sources and recyclable electrode materials are making resistance an environmentally responsible choice.

Conclusion

In conclusion, resistance welding stands as one of the most reliable and efficient metal joining processes in industrial manufacturing. Its ability to produce clean, strong, and repeatable welds without additional materials makes it invaluable across automotive, electrical, and aerospace industries.

With the continuous development of automation and digital control systems, resistance will continue to evolve as a cornerstone of modern fabrication technology. Understanding its principles, types, and advantages ensures that industries can harness its full potential for productivity, quality, and sustainability.